Top-down construction method

1. Introduction

The top-down construction method is a solution for simultaneously building the underground portion (below EL. 0) and the superstructure (above EL. 0) of a high-rise project, helping to optimize the schedule and make efficient use of the available space. In this method, the diaphragm walls, floor slab, and temporary steel columns (kingposts) play essential roles in bearing the loads and stabilizing the structure. The construction process begins with the construction of the diaphragm walls (which later become the enclosure for the basement) along with bored piles and the kingpost system. Then, while the underground levels and foundations are constructed from top to bottom (similar to the semi top-down method), some floors of the upper structure are also built simultaneously, ensuring continuity and significantly shortening the construction time.

The top-down construction method has prominent advantages in addressing space and schedule issues, making it particularly suitable for high-rise urban projects in limited spaces. This method does not require large excavation areas for the foundation and saves costs on constructing independent retaining walls. Moreover, the construction schedule is accelerated because the upper floors can be built while the foundations and basement levels are still under construction. There is no need to use a temporary bracing system to support the basement walls, which helps save costs and reduces complexity, as temporary bracing systems are often cumbersome and costly. The diaphragm walls and floor slab serve as the earth retention system, providing high stability to the excavation walls during construction. Additionally, by constructing directly on ground level, this method reduces the need for formwork and scaffolding systems for the floor slab. In densely populated urban areas, open cut excavation typically creates risks, such as lowering the groundwater table, which can cause slope failure or settlement of adjacent buildings, but with the top-down approach, these issues are significantly mitigated. Furthermore, when constructing basements with an already completed ground floor, this method minimizes the impact of weather on the construction schedule.

However, top-down construction also has some disadvantages, mainly related to the complexity of the structure and high technical requirements. The columns of the basement must have sufficient load-bearing capacity, and the connection between the beams and the wall columns requires high precision, making construction more challenging. This method requires a highly skilled and experienced construction team. The work in the confined basement space limits mechanization and impacts the health of workers, necessitating the installation of ventilation and artificial lighting systems to ensure safe and efficient working conditions.

2. Scope of application

-

The top-down technology is effectively applied to projects with deep basement levels (more than 3 basements).

3. Construction sequence

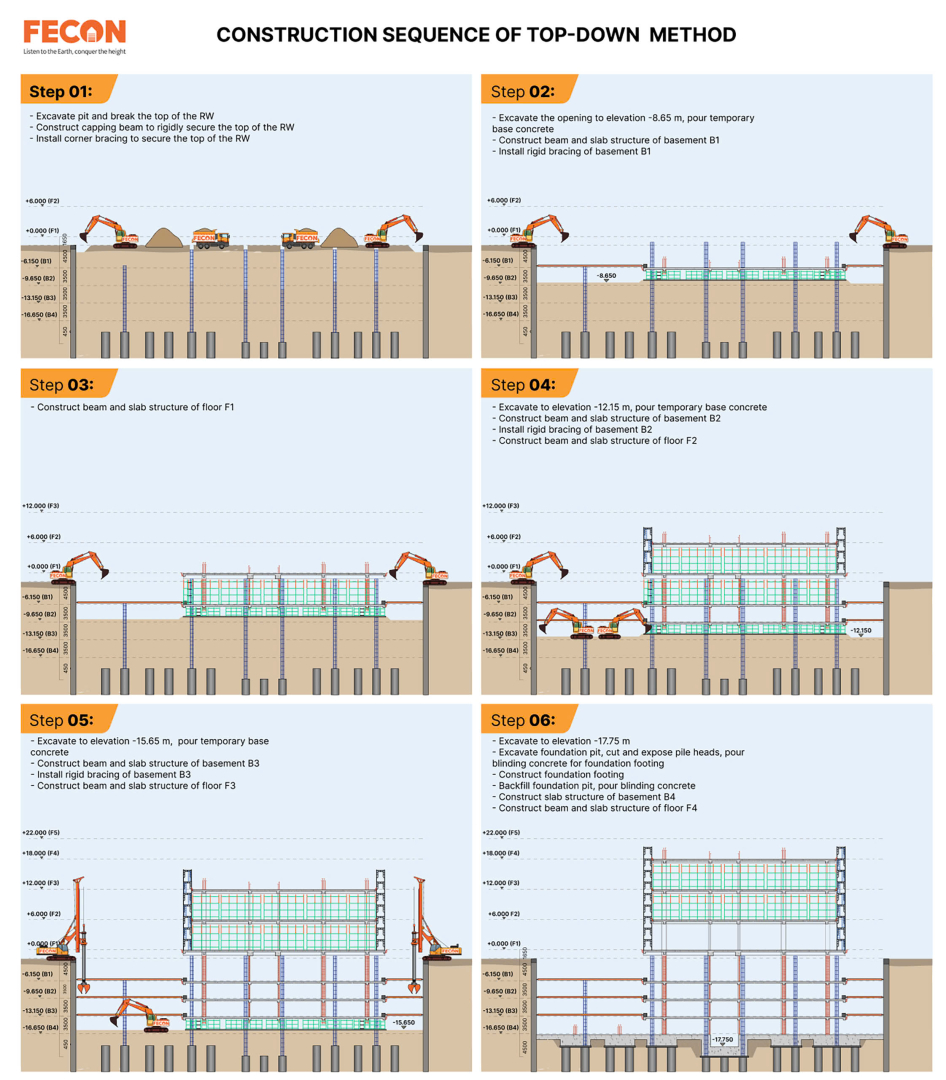

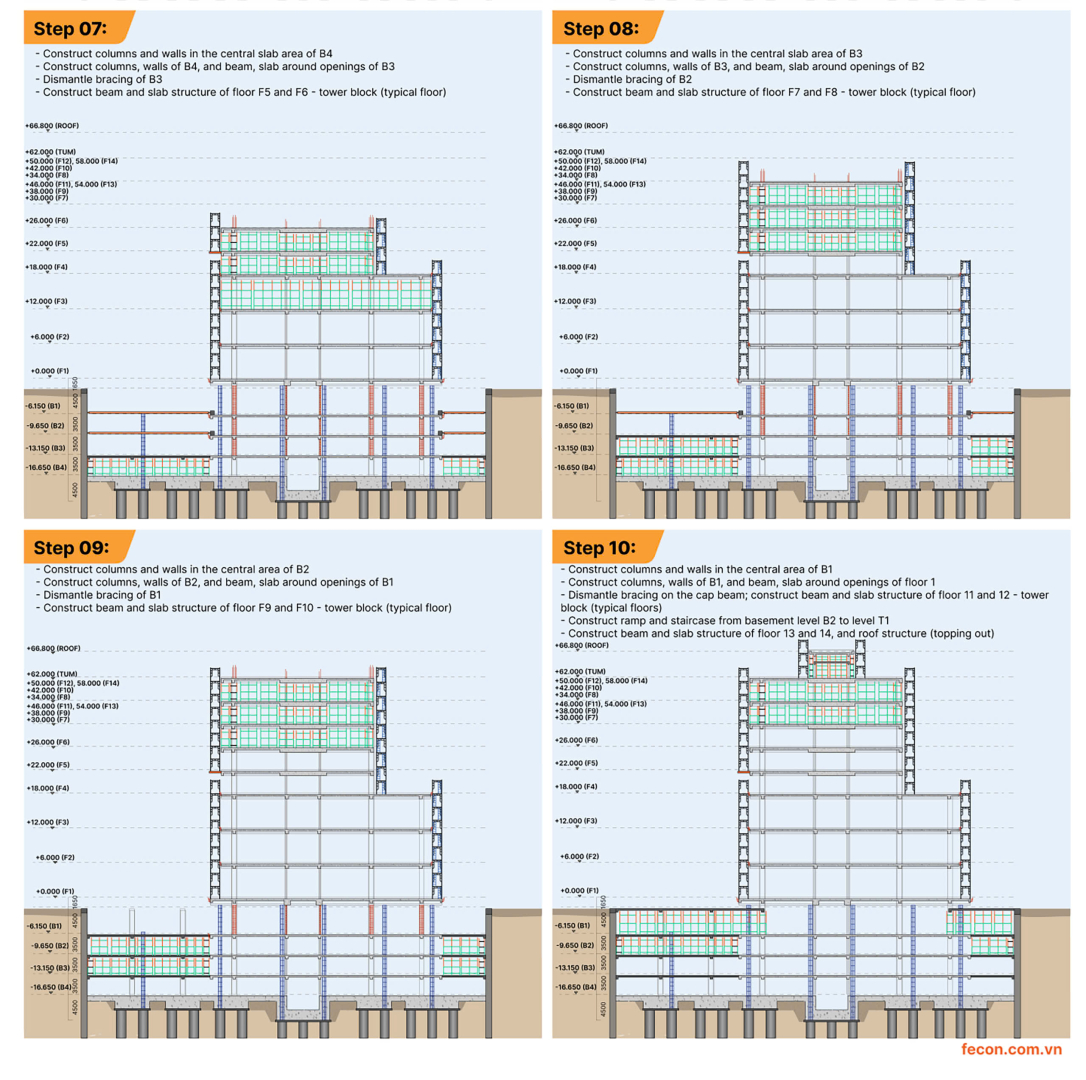

The construction process for a top-down method with a 3-basement project is illustrated in Fig. 1.

Figure 1. Construction process for a top-down method with a 3-basement project

REFERENCES

- Foundation and Soil improvement

- Large diameter soil-cement column (RAS) construction method

- Shaft grouted bored pile construction method

- Deep vibro stone columns

- Prefabricated Vertical Drain (PVD) combined with vacuum preloading technology

- PHC piles installation by SIP machine

- Pre-bored pile (BASIC) installation

- Diaphragm wall construction

- Other technologies

- Underground Construction

- Infrastructure Construction

- Building and Plant construction