Deep vibro stone columns

1. Introduction

The deep vibratory compaction technology, invented by Johann Keller in the 1930s in Germany, is a ground improvement method using vibrational energy. Among its applications, deep vibro stone columns are widely used for reinforcing soft clay soils. This technique involves forming compacted columns of aggregate within the soil, which serve to: (1) reduce settlement; (2) improve load-bearing capacity; (3) mitigate liquefaction potential; and (4) expedite drainage and consolidation of the soil foundation.

During construction, a deep vibrator is used to create stone columns of specified diameter and depth, densifying the surrounding soil layers to increase foundation stability. Typical stone column diameters range from 0.7 to 1.2 m, with spacing between columns set at 1.5 to 3.0 m, depending on design requirements. Stone columns can reach depths up to 20 m, making this technique highly effective for strengthening foundations in soft soils.

2. Scope of application

Due to its adaptability, deep vibro stone column technology is widely applied to reinforce various soil types, including loose sandy silt, soft clay, very soft silty soil, clayey silt, and peat. Specifically, deep vibro stone columns are suitable for large-scale projects such as transportation infrastructure, port facilities, industrial buildings, plants, and storage tanks.

3. Construction sequence

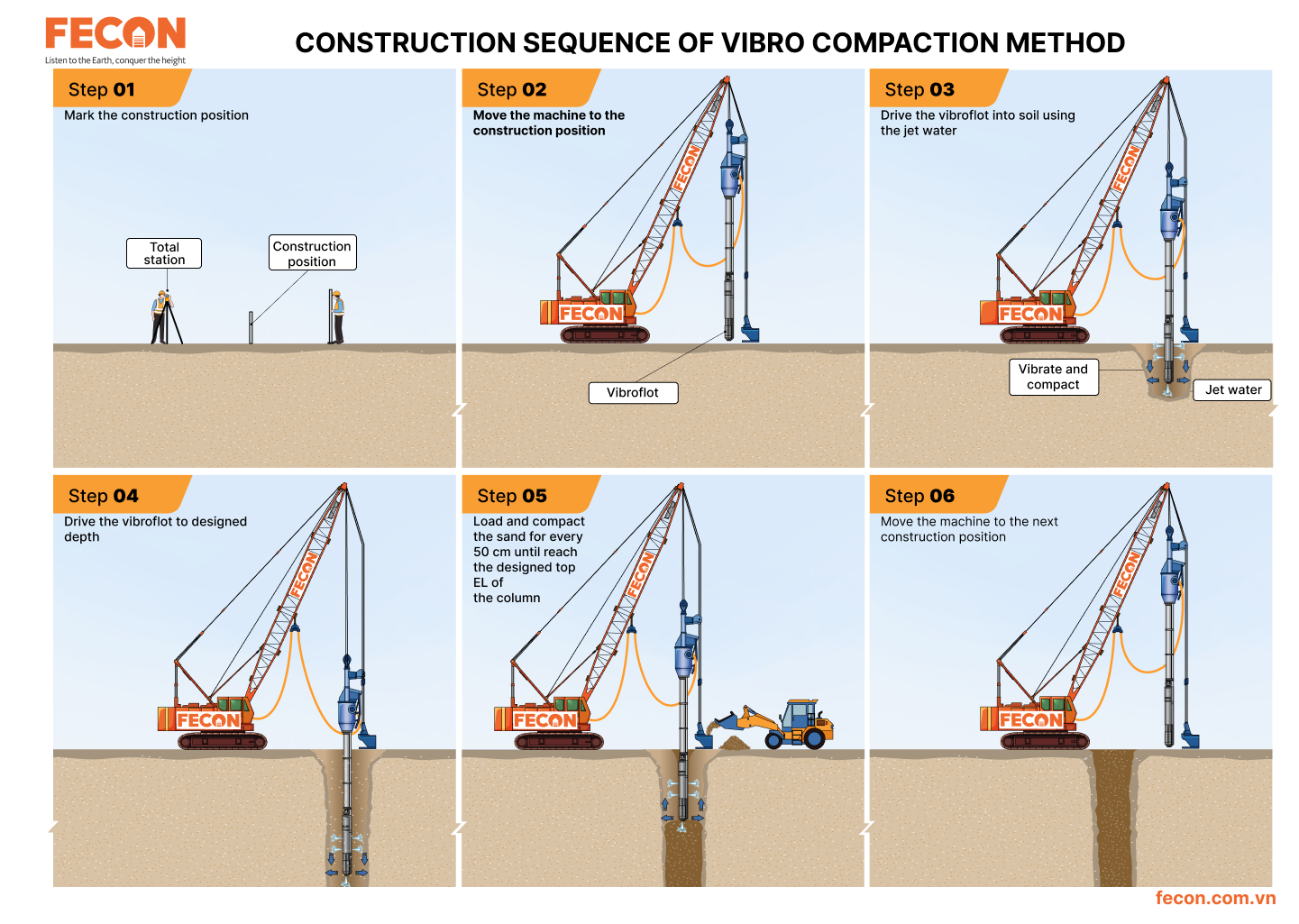

There are 02 common methods for installing deep vibro stone columns: (1) bottom-feed (dry process) and (2) top-feed (wet process). The process of stone column construction using the bottom-feed method is illustrated in Fig. 1.

Figure 1. Construction sequence of stone column construction using the bottom-feed method

4. Technology video

REFERENCES

[1] VSSMGE. (2023, November 25). Công nghệ đầm rung sâu xử lý nền móng công trình tại Việt Nam. Hội cơ học đất và Địa kỹ thuật công trình Việt Nam. https://vssmge.org/cong-nghe-dam-rung-sau-xu-ly-nen-mong-cong-trinh-tai-viet-nam/.

[2] Barksdale, R. D. and Bachus, R. C. (1983). Design and Construction of Stone Columns, Volume I. US Department of Transportation, Federal Highway Administration (FHWA), Publication No.: FHWA-RD-83-026.

[3] Minh, P. V. (2022). Nghiên cứu giải pháp thiết kế thiết bị thi công cọc đá trong điều kiện Việt Nam. Tạp chí Khoa học Công nghệ Xây dựng (TCKHCNXD)-ĐHXDHN, 16(5V), 46-56.

- Foundation and Soil improvement

- Large diameter soil-cement column (RAS) construction method

- Shaft grouted bored pile construction method

- Deep vibro stone columns

- Prefabricated Vertical Drain (PVD) combined with vacuum preloading technology

- PHC piles installation by SIP machine

- Pre-bored pile (BASIC) installation

- Diaphragm wall construction

- Other technologies

- Underground Construction

- Infrastructure Construction

- Building and Plant construction