Large diameter soil-cement column (RAS) construction method

1. Introduction

The large-diameter soil-cement column (RAS) construction method is a deep mechanical mixing method used for ground stabilization. In this method, soft soil is mixed with cement grout using a dual-rod, twin-blade system with independent and counter-rotating blades, ensuring high-quality, uniform piles. The inner rod, attached to a high-torque drill bit, penetrates the soil, while the outer rod facilitates the cement-soil mixing. This counter-rotational mechanism achieves a superior mix quality compared to traditional Cement Deep Mixing (CDM) methods, with RAS capable of creating piles up to 2.5 m in diameter.

Compared to traditional CDM methods, the RAS construction method has the following advantages:

- Positioning System: The “equipment guidance” function allows for accurate guidance of construction machinery using RTK-GNSS, which provides real-time positioning information with 2-3 cm horizontal accuracy and 3-4 cm vertical accuracy via a mobile station on the drill rig or a base station.

- Safety: risks to workers from direct exposure to the drill rig are minimized.

- Real-Time Monitoring-Control System: The “Monitoring-Control System” allows engineers to monitor work progress in real time.

- Compatibility: The “Monitoring-Control System” is compatible with both deep mixing and shallow mixing methods (mass stabilization - block stability type B).

- Remote Monitoring System: Work progress can be remotely monitored from outside the drill rig using an external screen.

Table 1. Comparison between RAS and Traditional CDM Technologies

| Attribute | RAS Technology | Traditional CDM Technology |

| Pile Diameter (mm) | 1400 - 2500 | 400 - 1200 |

| Uniformity | - Uniform column quality due to specialized drill head design, eliminating “turning together” issues in cohesive soils | - Does not fully eliminate this issue |

| Backflow | - Smooth backflow with uniform mixing, sludge lifted gently via screw rotation around the drill rod, reducing impact on surrounding structures | - Rougher backflow, lacks screw rotation for efficient material lifting |

| Drilling Capacity | - Independent twin-blade system allows for efficient penetration of hard soil layers | - Limited penetration in hard soil layers |

| Quality Control | - Synchronized computer-based real-time monitoring system | - Asynchronous control system |

This technology has seen extensive application in major projects in Japan since the early 21st century. In Vietnam, FECON introduced RAS technology for the first time at Berths 5 & 6 of Lach Huyen Port, Hai Phong.

2. Scope of application

- Ground improvement and settlement prevention for civil, industrial, and transportation structures

- Use as retaining walls

- Liquefaction prevention

- Slope and embankment stabilization

- Prevention of uplift

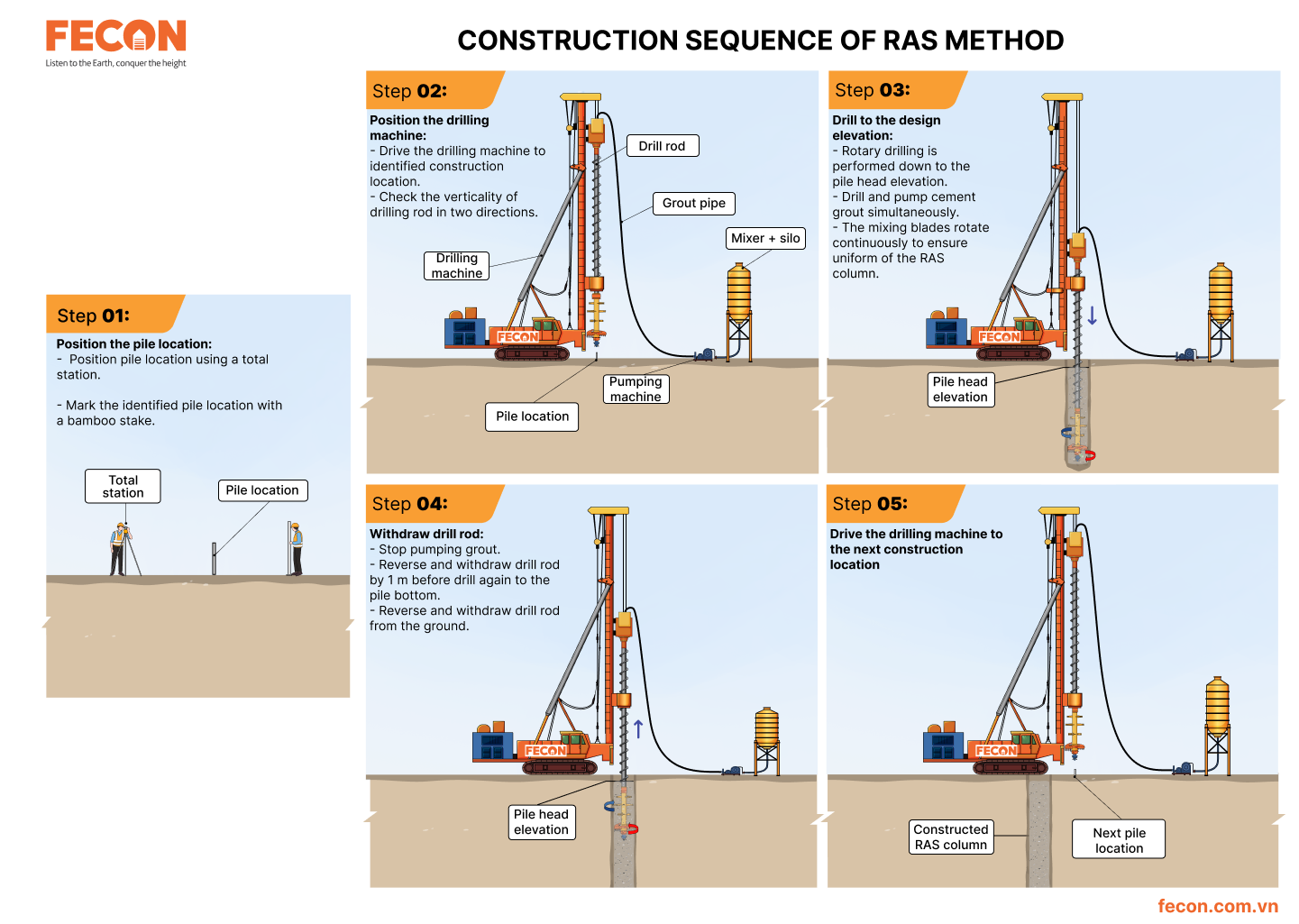

3. Construction sequence

The RAS column construction sequence consists of the following main steps.

Figure 1. RAS column construction sequence

4. Technology video

REFERENCES

[1] Raito Kogyo (2013). Technical publication for high-pressure injection mixing method, p11 (in Japanese)

[2] Kenji Mori et al. (2020). Invited lecture: recent trends in the development of deep mixing methods in Japan

[3] Japan Cement Association (1985). Manual for ground improvement using cement binder (in Japanese).

[4] RASS Column Association (2016). Design and construction manual for RAS COLUMN Method (in Japanese).

[5] TCVN 9403:2012. Gia cố nền đất yếu – phương pháp trụ đất xi măng

- Foundation and Soil improvement

- Large diameter soil-cement column (RAS) construction method

- Shaft grouted bored pile construction method

- Deep vibro stone columns

- Prefabricated Vertical Drain (PVD) combined with vacuum preloading technology

- PHC piles installation by SIP machine

- Pre-bored pile (BASIC) installation

- Diaphragm wall construction

- Other technologies

- Underground Construction

- Infrastructure Construction

- Building and Plant construction