Prefabricated Vertical Drain (PVD) combined with vacuum preloading technology

1. Introduction

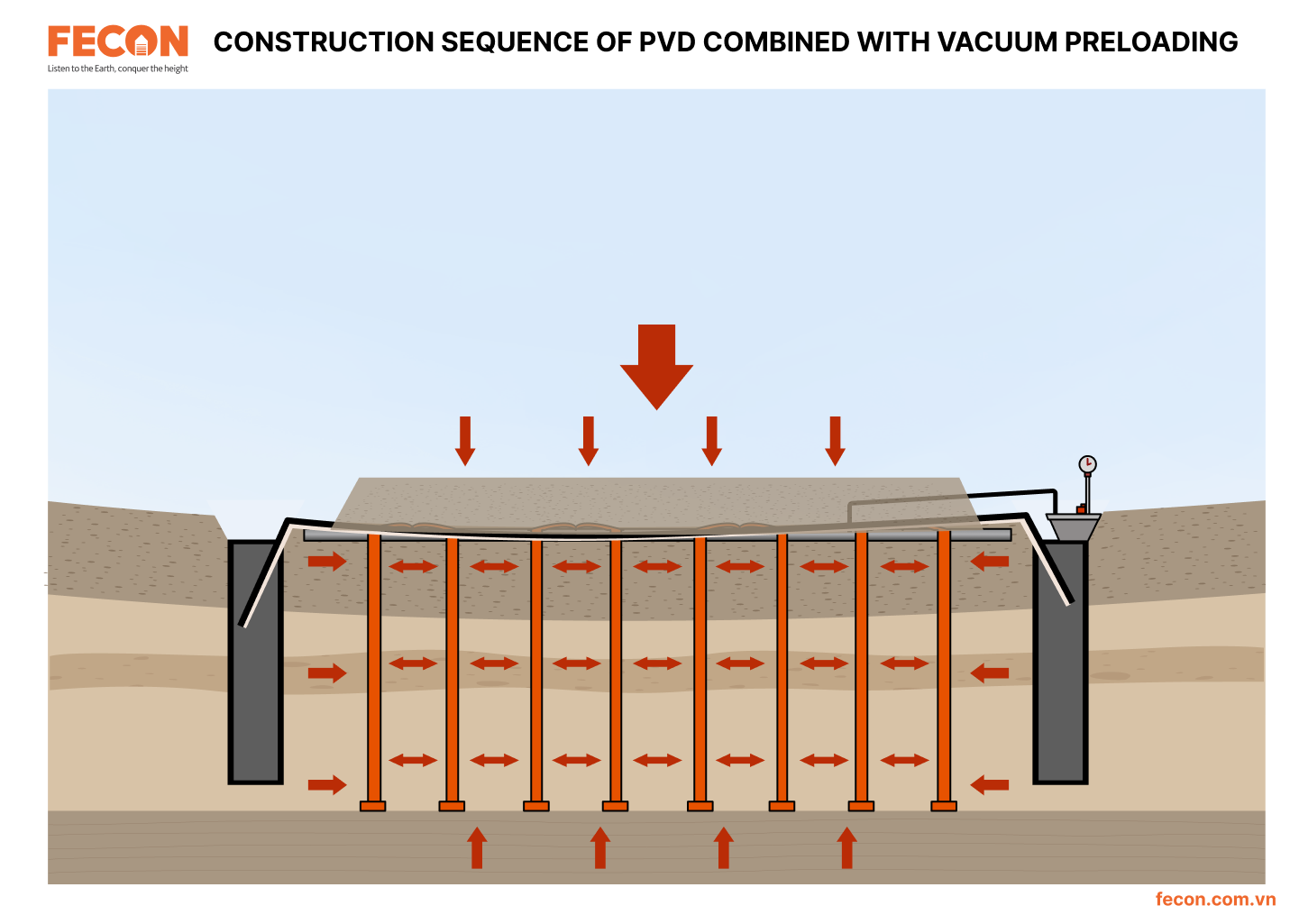

The Prefabricated Vertical Drain (PVD) technology combined with vacuum preloading is a widely adopted solution for soft soil improvement (Fig. 1). Vacuum preloading applies negative pressure through vacuum pumping, maintained by an airtight membrane system. This method increases effective stress by reducing pore water pressure in the soil while keeping total stress constant, thereby accelerating soil consolidation. In this technology, PVDs facilitate the transmission of vacuum pressure into the soil, causing the surrounding soil to move inward toward the vacuum zone. This inward movement reduces outward soil displacement due to the surcharge loading, minimizing the risk of slope instability during embankment construction. Additionally, achieving a stable vacuum pressure of 60 - 70 kPa (equivalent to a 4 m embankment load) takes only 6 - 8 days, much faster than conventional preloading methods.

Figure 1. PVD combined with vacuum preloading

Compared to traditional PVD with surcharge loading, vacuum - PVD technology offers numerous advantages. Primarily, this technology reduces the required amount of surcharge sand and the size of the counterweight berm, optimizing material costs. Furthermore, the technology does not require extensive land area, making it suitable for projects with limited space. Construction time is also significantly reduced compared to conventional PVD and surcharge preloading under similar load and consolidation requirements. These advantages make the vacuum - PVD solution a more cost-effective and efficient ground improvement method.

However, effective implementation of the PVD-vacuum method requires skilled engineers with specialized technical expertise. Additionally, the effectiveness of this technology may be limited in soil profiles containing sand layers with high permeability, which can complicate stable vacuum pressure maintenance.

2. Scope of application

The vacuum – PVD technology is used to replace or reduce surcharge load in preloading applications, particularly for consolidating soft clay soils with a vertical drainage system using PVDs. For treated ground containing drainage-prone layers, these layers must be isolated with an airtight barrier, such as clay walls, to ensure stable vacuum pressure and maximize effectiveness.

3. Construction sequence

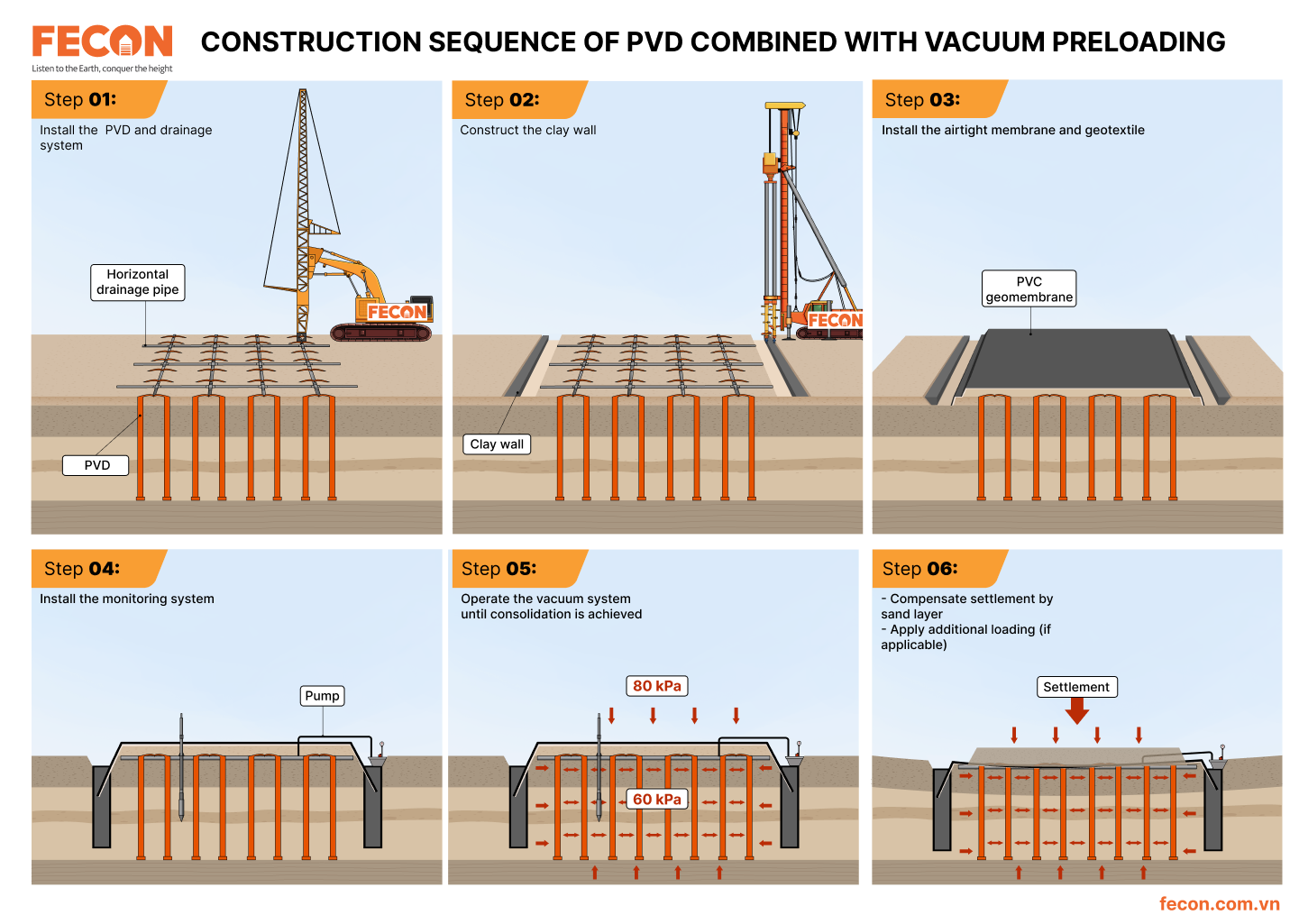

The construction sequence for the vacuum – PVD technology is illustrated in Fig. 2.

Figure 2. Construction sequence for the vacuum – PVD technology

4. Technology video

REFERENCES

[1] Bergado, D., Chai, J., Miura, N., Balasubramaniam, A. (1998). PVD improvement of soft Bangkok clay with combined vacuum and reduced sand embankment preloading. Geotechnical Engineering, 29(1).

[2] Chai, J.C., Carter, J., Hayashi, S. (2006). Vacuum consolidation and its combination with embankment loading. Canadian Geotechnical Journal, 43(10), 985-996.

[3] Chai, J.-C., Shen, S.L., Miura, N., Bergado, D. T. (2001). Simple method of modeling PVD-improved subsoil. Journal of geotechnical and geoenvironmental engineering, 127(11), 965-972.

[4] Chu, J., Yan, S., Yang, H. (2000). Soil improvement by the vacuum preloading method for an oil storage station. Géotechnique, 50(6), 625-632.

[5] Hird, C., Pyrah, I., Russel, D. (1992). Finite element modelling of vertical drains beneath embankments on soft ground. Géotechnique, 42(3), 499-511.

[6] Indraratna, B., Redana, I. (2000). Numerical modeling of vertical drains with smear and well resistance installed in soft clay. Canadian Geotechnical Journal, 37(1), 132-145.

- Foundation and Soil improvement

- Large diameter soil-cement column (RAS) construction method

- Shaft grouted bored pile construction method

- Deep vibro stone columns

- Prefabricated Vertical Drain (PVD) combined with vacuum preloading technology

- PHC piles installation by SIP machine

- Pre-bored pile (BASIC) installation

- Diaphragm wall construction

- Other technologies

- Underground Construction

- Infrastructure Construction

- Building and Plant construction